3D Scanning

Increase measurement accuracy for design and avoid problems during installation.

While tape measures, levels, and other traditional tools of the trade will always have their place in pipeline engineering and design work, technology is transforming the way we measure and design facilities with impressive results. Since keeping field welds to a minimum is always desirable, and no one wants the hassle and expense of rework, leveraging the best technology to get the dimensions right, right from the get-go, is an advantage that natural gas and hazardous liquid pipeline and facility operators are eagerly embracing.

Tap into comprehensive 3D scanning and design services that put your project on the right track.

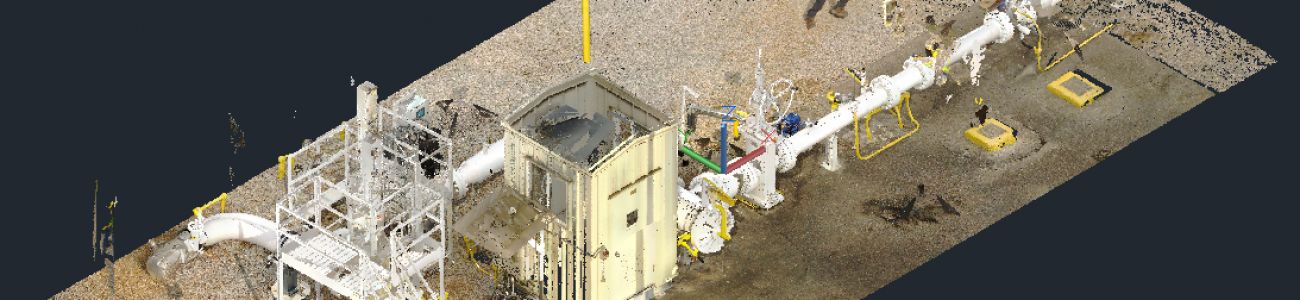

HT Engineering uses a state-of-the-art three-dimensional scanner that can be effectively deployed on new and retrofit pipeline design projects. The scanner works by emitting laser beams to capture a spatial representation of a project site, generating a highly accurate 3D Computer-Aided Design (CAD) model. If desired, the scans can be geolocated to tie in with other survey data. Our engineers and designers can work with and within the model to design new and retrofit piping and facilities that will fit in the field. The technology is especially advantageous for retrofit projects where it’s likely that the existing infrastructure is congested, or where piping is less than square with off-angles that are easy to miss with traditional manual tools. Having the detailed and accurate spatial information allows us to avoid conflicts and fabricated pieces that don’t line up when it’s time for installation.

For projects and sites that are good candidates for scanning, HT Engineering offers comprehensive scanning support, including:

- Prep work: Support prepping the project site for the best possible scan results

- Scanning: We scan the location and project from multiple angles using our portable scanner and experienced scanning technicians

- 3D model files: We can provide access to the scans and 3D model or “point cloud” in formats supported by your internal software

- Facilitated reviews: Our experts can virtually walk you through the model to facilitate procedure and design reviews and scenario planning exercises

- Comprehensive design, fabrication, and installation services: Leveraging the scans and models, our designers can see your project through every phase to completion, saving time and resources in the process

Ensure smoother projects, better fit, and a safer working environment.

3D scans are the key to projects that stay on track and ultimately achieve the results you expect while avoiding unnecessary pipeline downtime and keeping your field team safe. More accurate models lead to more accurate designs and fabrications, which means less field welding, less installation stress on pipelines and fittings, and less work in unpredictable field conditions.