Expert perspectives on oil and gas

pipeline matters, trends, and best practices.

As the go-to engineering partner for pipeline operators in the Midwest, HT Engineering is committed to sharing our latest thinking about innovations, regulatory changes, and other critical issues impacting the ways in which pipelines are designed, constructed, operated and maintained. Get access to our views and ideas here.

Refine Results

Building a successful integrity team

Working across multiple companies, disciplines, and personality types can be a challenge. However, by focusing on clear and consistent communication, actively inviting feedback, building relationships, and documenting team knowledge as outlined above, you can build a high performing team that is up to the challenge – and most of the time, enjoys facing the challenge together.

Read the Article

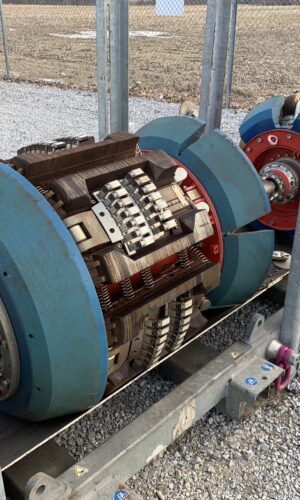

Five Key Ways to Protect Yourself from Pipeline Surge

Surge is a potential issue in liquid pipeline operation. It’s relatively rare in a line that’s operating normally, but as we’ll see, there can be serious consequences when it does happen. Fortunately, there are steps that pipeline operators can take to prevent surge from happening, to reduce the magnitude of the surges and to minimize risks and damage from surges.

Read the Article

Back to basics – the benefits of cathodic protection

The response to cathodic protection (CP) varies from company to company and manager to manager. Some understand its importance and give it the time and funding it requires to be effective, but others don’t see much value in it at all.

Read the Article

How to manage fugitive emissions by reducing potential leak points

Our world is facing a growing need to reduce emissions of planet-warming greenhouse gases. As a result, the pipeline sector is facing increasing regulatory and public pressure to reduce its impacts through unplanned or fugitive emissions. Some pipeline operators also feel regulatory pressure to manage emissions to maintain their air quality permits, which are based partly on the number and type of fittings in a facility.

Read the Article

What if your burst pressure calculation results don’t make sense?

It was supposed to be an uneventful second-round in-line inspection tool run through a liquids pipeline about 100 miles long. But it stopped being ordinary when analysis of the tool run data found 1,800 crack-like features that met burst pressure remediation criteria and were potentially hazardous to the integrity of the line.

Read the Article

Five steps to get ready for that upcoming in-line inspection tool run

ILI inspections are essential for meeting regulatory guidelines, and are also essential for an operator to be able to understand threats that may have been previously unknown.

Read the Article

New Regulations for Gas Gathering Pipelines

With increasing demand for natural gas and the success of shale play hydraulic fracturing in the last decade and a half, production in some areas of the United States has surged. Gathering lines have followed suit, with dramatic growth in both mileage and pipe diameters

Read the Article

Five key learnings about pipeline integrity from PPIM

Industry events like the recent Pipeline Pigging and Integrity Management (PPIM) conference in Houston are great places to identify trends and understand what the industry will be focusing on in the near future. HT Engineering sent a delegation to and hosted a trade show booth at PPIM 2022.

Read the Article

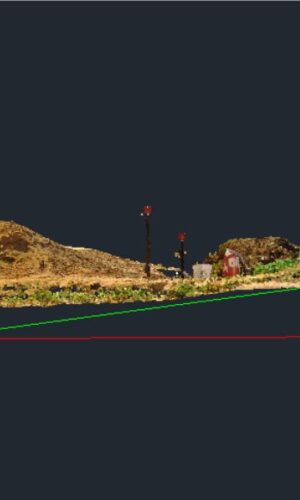

How 3D scanning technology prevents mistakes during piping replacements

Making mistakes can be embarrassing, but it’s how you respond to those mistakes that separates the ordinary from the excellent.

Read the Article

Six keys to designing pipeline systems for winter realities

As the northern climes head into winter, it’s a good time to think of how to design pipeline systems for reliable service in cold temperatures. Even if changing weather patterns send warmer temperatures our way at times, unusually cold snaps may also become part of the “new normal.”

Read the Article